BUSINESS

Navigating Uncharted Territory

ADAS and the Art of Aftermarket Product Development

By Douglas McColloch

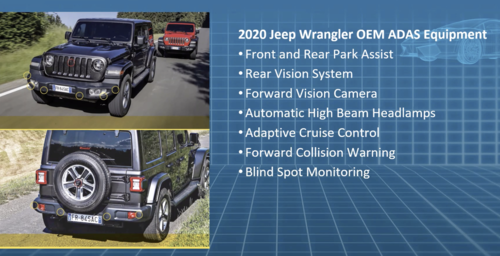

vehicle platforms. Even vehicles as relatively unsophisticated

as the Jeep Wrangler come equipped with a full suite of

onboard driver-assist systems that must be taken into account

when designing and installing aftermarket components.

The advent of advanced driver-assistance systems (ADAS) in OE vehicle platforms presents the aftermarket with one of its greatest near-term opportunities and some of its most daunting challenges. Modifying a vehicle in virtually any way can affect the ability of ADAS to function properly, and the same holds true for collision repair and refinishing.

Regardless of the nature of the work, a vehicle’s sensors must be properly repositioned, its cameras correctly repointed and its control modules successfully reprogrammed when modifications are made, and even the smallest variation from the factory OE geometry can adversely affect a vehicle’s performance and drivability.

But for companies that can solve those problems and integrate new products with ADAS-compatible vehicles, the opportunity to expand market reach is considerable. A recent SEMA Education webinar, “ADAS Technologies: How to Navigate Product Development,” aimed to provide answers by featuring case studies from two leading aftermarket manufacturers that have successfully developed and launched products for ADAS-equipped vehicles.

Moderated by SEMA Vice President of OEM and Product Development Mike Spagnola, the webinar discussed the types of ADAS systems that can pose the most difficulties to builders and modifiers, the testing and calibration protocols that are the most efficient, and the tools and logistical support that are needed to enable successful product integration.

point-of-view data for relocated sensors before physical

testing occurs. When the sensors are reinstalled,

repositioned and recalibrated, they will restore coverage to

OE specifications.

Compliance: Concept to Execution

The webinar commenced with a presentation from John Natoci, chief operating officer at American Expedition Vehicles (AEV), who focused on the Jeep Wrangler, one of the aftermarket’s most heavily modified vehicle platforms. AEV manufactures a plethora of parts for Wranglers, including bumpers, winches, lightbars and lights, and Natoci said that every one of them will have some impact on the factory ADAS. The key to successful product development, therefore, is to factor in ADAS requirements early in the design process, before pen is put to paper.

“We had to learn to bake this into the process early rather than after the fact,” Natoci said. “We weren’t used to having to deal with it, and our designers and engineers found out the hard way later on that we had issues. It was a paradigm change for us, to make sure that everyone was thinking ahead and not having to learn by trial and error later.”

methodologies (yet), companies may need to resort to a little

MacGyvering for physical testing. In the case of AEV’s

bumper/spare tire carrier, the company used a roll of green

masking tape, cardboard, and some Quikrete cylinders bought

from Home Depot to create the “grid” that the company used

for FMVSS testing. It’s not pretty, but it worked.

While the Wrangler is not the most sophisticated in terms of advanced tech, Natoci said, its suite of onboard ADAS is comparable to other, more technologically advanced cars and trucks. The first step, then, is to identify a new product’s potential impacts on the Jeep’s ADAS. Among the potentially disruptive factors are increased curb height, new bumper geometry, revised wheel offset or increased tire diameter.

“Even the smallest changes can have a significant impact,” Natoci noted.

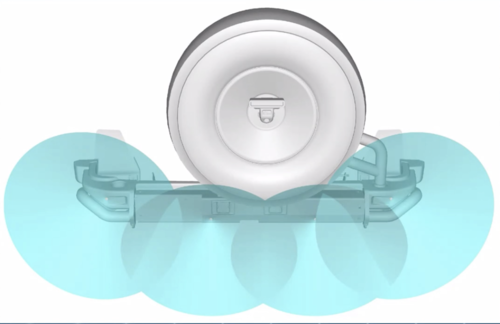

Once ADAS problem spots are identified on a bumper, for instance, designing can commence. To provide an example, Natoci spotlighted an AEV rear bumper/spare-tire carrier that necessitates relocation of the factory backup and parking sensors as well as the center high-mounted stop lamp (CHMSL). Using CAD software, AEV engineers simulate the field of view of the relocated sensors, looking for potential points of interference while calculating angles to restore sensor coverage to factory specifications.

Next comes physical testing—in this case, in accordance with Federal Motor Vehicle Safety Standard (FMVSS) No. 111. The first step involves modeling a baseline of the unmodified vehicle, which will provide the needed data to recalibrate the sensors once they’ve been relocated.

Next, a test mule is mocked up with the relocated sensors and then subjected to testing. The data gathered here can be compared to the unmodified baseline data gathered previously.

“Like a lot of companies these days, we do a lot of 3-D printing, which allows us to try out all sorts of design iterations and adjust as needed,” Natoci said. In this case, that enabled AEV to fine-tune the size and shape of the housing for the CHMSL relocation kit until the proper positioning and angularity were achieved.

Then comes actual proving-ground testing, which often involves partnering with third-party test facilities. Once compliance with the relevant FMVSS standards has been achieved, an AEV technician will plug into the vehicle using (usually) the supplied OE diagnostic software to verify that all ADAS sensors are functioning as intended with no trouble codes noted.

of sensor housings in a cost-effective manner. Here, a 3D-

printed housing for a Jeep’s CHMSL relocation kit can be fine-

tuned and reprinted as necessary until the proper alignment

and angularity are met.

Other Considerations

However, modifiers tend to keep modifying, so it’s important that users also be given the necessary tools to keep their vehicles in compliance as they continue to tinker with their rides. In AEV’s case, every suspension system it makes comes with an electronic snap-on module to account for future changes in tire diameter, tire pressure, axle ratios and the like.

Moving up the vehicular pecking order, ADAS compliance poses its own unique set of challenges to more technologically complex “signature” or coach-built vehicles. Corry Davis, vice president of engineering at Saleen Automotive, noted that the ADAS systems most affected by changes to Saleen’s signature F-trucks and Mustangs are adaptive cruise control, collision avoidance, lane-keeping assist and rear parking assist.

“With the Mustang, there’s also radar as well as the cameras that have to be aligned and accounted for,” Davis said. “Vehicles equipped with collision avoidance and/or adaptive cruise control have a forward-facing radar unit that must be calibrated when installed or moved. Before calibration, you must ensure that the sensor face is perpendicular to the ground, then use the diagnostic scan tool to set the calibration for the CCM [central control module].”

That generally requires about 15 minutes of on-road testing while running the calibration procedure with the OE scan tool.

Another relatively new ADAS technology to consider is 360-degree camera view.

“As you take the rake out of the stock vehicle when you lift it or lower it, the alignment of these cameras needs to be redone,” Davis said.

A Saleen technician will connect a factory diagnostic tool to the vehicle’s CCM and follow the on-screen instructions. To verify that the alignment has been successful, the vehicle is taken to a parking lot with straight parking lines. Driving over the lines slowly while watching the infotainment screen will reveal whether the camera view is partial or “segmented” (in which case another alignment is needed) or “unsegmented” (in which case the vehicle is in compliance again).

ADAS technology, and they are also affected by being lifted

above or lowered below their factory positions. Saleen uses a

parking lot with solid striping to test the repositioned camera’s

point of view to ensure that a “segmented” partial view of the

road does not occur when in use.

How SEMA Can Assist

No matter the test methodology, ADAS compliance testing and verification can be costly and time-consuming. It requires ample, level shop space for target positioning, and it requires special tools that can costs tens of thousands of dollars, which may be beyond the budgetary limits of many smaller companies. There are also no industry-wide standards for nomenclature, testing or calibration, which further adds complexity and cost for smaller operations.

To better assist member companies in the manufacture and testing of ADAS-compliant products, SEMA’s new state-of-the-industry SEMA Garage facility, located in metro Detroit and scheduled to open in early 2022, will incorporate a 5,000-sq.-ft. shop space dedicated exclusively to ADAS testing.

In addition to the dedicated space, two ADAS engineers will be on staff, and two static on-site calibration centers will employ both OE and aftermarket tools and equipment. Additionally, SEMA will purchase 20 new vehicles in the coming year to use as test beds in both stock and modified (e.g., lifted or lowered) configurations. Test procedures will be both static and dynamic—the latter to be done off-site in cooperation with Detroit-area test tracks. The end goal of the program is to assist industry partners in more fully understanding ADAS, particularly on modified vehicles.

“This is all-new territory for a lot of us,” Spagnola noted. “SEMA is investing a half million dollars in tools for the Garage, and they belong to our members. We’ll have technicians on hand to answer questions, and members will be welcome to bring their modified vehicles to our Garage, and we’ll work right alongside them.”

Looking forward a few years, the emergence of artificial intelligence “auto-pilot” features will present their own sets of challenges to modifiers, Davis said.

“Camera placement and how the camera works with the engine control module is a big concern right now—specifically in terms of what we’re limited to, based on where everything needs to go,” he explained.

Still, Natoci remains optimistic.

“A few years ago, you could panic and say, ‘We’re going to get locked out of the market,’” he said of advances in onboard OE technologies. “I think the aftermarket has proven that we can move with it, and I also think the OEMs understand that. There was a time when I think that they were trying to lock folks out—intentionally or unintentionally—but I think they see the benefit of aftermarket involvement now. So it’s not going to get any easier, but I don’t see aftermarket-modified vehicles going away any time soon.”

About SEMA Garage Detroit

About SEMA Garage Detroit

Three times larger than SEMA’s Diamond Bar technical facility, SEMA Garage Detroit, scheduled to open in early 2022, will be a state-of-the-art emissions testing lab and ADAS research and development center, with a staff of full-time technicians on hand to assist SEMA-member companies with product testing and development.

SEMA Garage Detroit will include new equipment such as emissions and horsepower testing for all-wheel-drive and diesel vehicles. It will also house vehicle lifts, fabrication equipment, an alignment rack, 3-D scanning tools, and engineering software. In addition to the 5,000-sq.-ft. ADAS testing facility, the Garage’s new emissions lab will be purpose-built to accommodate a 48-in., all-wheel-drive chassis dynamometer and will include equipment that meets the California Air Resources Board’s new 1066 testing requirement standards.

For further information about the SEMA Detroit Garage and its many programs and services, visit www.semagarage.com.