By Mike Imlay

The SEMA Garage has undertaken groundbreaking research into the interplay between ADAS and aftermarket modifications, starting with the '22 Chevrolet Silverado.

Disclaimer: The information contained herein is only applicable to the specific '22 Chevy Silverado LTZ vehicle used in the SEMA Garage research and the specified modifications and shall not be construed to indicate any results from additional modifications to the '22 Silverado or for the modification of any other vehicle.

In May, the National Highway Traffic Safety Administration (NHTSA) issued a notice of proposed rulemaking (NPRM) relating to the adoption of a new Federal Motor Vehicle Safety Standard (FMVSS) to require automatic emergency braking (AEB), including pedestrian AEB, systems on light vehicles. These systems utilize various sensors and components to automatically apply a vehicle's brakes in a crash-imminent situation when a driver fails to brake enough or at all.

Under the proposal, OEMs would be required to meet all the standard's requirements within four years of publication. Small-volume manufacturers and alterers would have an additional year to comply.

NHTSA's projections suggest the rule could save hundreds of lives and prevent tens of thousands of injuries to drivers, passengers and pedestrians annually. If adopted, the rule could significantly impact the aftermarket.

"Depending on the type of modification, and the vehicle make, model and year, it may be illegal to knowingly manufacture, sell or install any product--including aftermarket equipment--that would take a vehicle out of compliance with any safety standard, including the vehicle-based standards," explained SEMA Senior Director of Federal Government Affairs Eric Snyder. "This is informally known as the 'make inoperative' provision. The implementation of a safety standard is what triggers the make-inoperative provision, and parts manufacturers must have a reasonable basis to conclude that their product won't take a vehicle out of compliance with the standard."

Currently, there is little data available to help anyone modifying an ADAS-equipped vehicle understand the exact degree of risk associated with changes to the vehicle. However, ongoing research at the SEMA Garage Detroit ADAS Research Center seeks to change all that.

Rapid adoption of ADAS features raises new challenges--and opportunities--for vehicle modifiers.

Through a groundbreaking study of typical modifications made to a '22 Chevrolet Silverado 1500 LTZ, Garage engineers now have insight into how the vehicle's ADAS responds to varying lifts, leveling, and wheel and tire modifications.

The findings will be presented first in an upcoming Wednesday, September 13, "A Modified Vehicle and the Effects on ADAS Functionality--A Case Study" virtual session for SEMA members, and then in a related white paper to be released in time for the 2023 SEMA Show this Fall. But before we get to that research, it's important to cover some background.

HOW WE GOT HERE

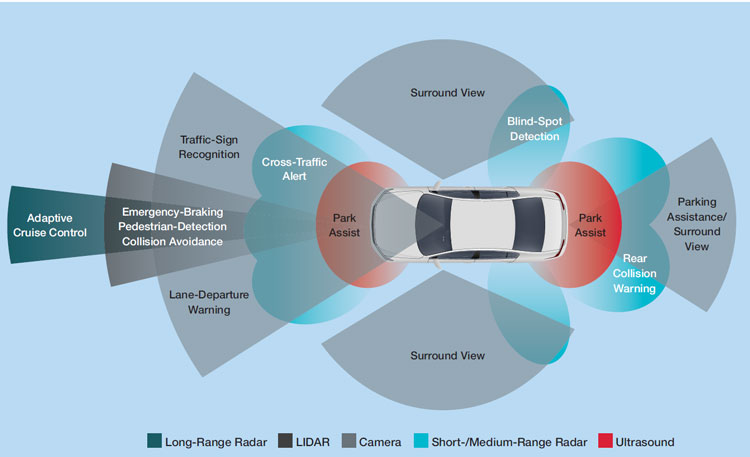

Over the past decade, OEMs have deployed a variety of ADAS features on their new vehicles. Through a complex mix of onboard computers, cameras, radars and other sensors, these systems help to warn drivers of imminent danger and/or to take actions to avoid or reduce the severity of impacts. Some of the most common ADAS technologies include adaptive cruise control, blindspot monitoring, lane-departure warning and lane-keeping, and the above-mentioned AEB, among others.

While adoption was slow at first, in recent years consumers have more than warmed to these safety-assistance technologies. In fact, many have come to expect them in one form or another when buying a new vehicle.

However, this rapid adoption continues to raise new challenges to the automotive industry--especially the specialty-equipment community. After all, the ability to appropriately modify, customize and accessorize vehicles drives aftermarket sales, and ADAS presents would-be modifiers and aftermarket suppliers with a considerable learning curve.

"With the exception of the newly proposed AEB rule, there are no ADAS standards," explains SEMA Aftermarket ADAS Engineer Mike Muller. "But the good thing about having no standards is that innovation is still occurring--so the product is getting better and better."

According to Muller, NHTSA tends to allow new ADAS technologies to shake out and improve, adopting a wait-and-see approach until a prevailing standard presents itself. "There's a moving target before there's a written standard. Technology takes a long time to standardize, but standards for many of these technologies are coming," he says.

Still, a lack of common standards has its downsides. The process of repairing and replacing parts on ADAS-equipped vehicles can be difficult and time-consuming.

There are numerous varieties of ADAS technologies, sensors and systems in the marketplace. OEMs themselves draw from multiple ADAS suppliers and the ADAS components can vary by vehicle make, model and year. Also, there are constant software updates that a repairer, installer or vehicle modifier must stay on top of. All of this results in hundreds of discrete ADAS repair, replacement and calibration procedures across the automotive market.

Plus, there's another consideration: The calibration process itself--the most crucial step in maintaining ADAS functionality on a repaired or modified vehicle--can get "spoofed," resulting in inaccurate readings.

This can happen due to numerous factors present in the testing environment. For example, a shop with limited space might inadvertently position a calibration target too closely to a vehicle sensor and unknowingly mimic a "successful" calibration. Proper calibration also requires a near-level floor surface or compensating equipment, which can pose additional challenges and costs for many shops and facilities.

The Silverado's ADAS functions were evaluated thoroughly before and after each modification, including through dynamic testing.

The challenge for aftermarket companies is obvious, Muller says. "We've got several types of SEMA members who are impacted. First, there are parts manufacturers who make product to modify a vehicle who need to know how it might affect ADAS function. And then we have our modifiers or installers. They're the buyers of these products. There are also glass and collision-repair businesses, among others. And then, ultimately of course, there are our consumers."

And those consumers are becoming increasingly alert to the potential consequences of non-compliant modifications.

Most OEM owner's manuals note that modifying a stock vehicle may result in malfunction of ADAS features and could lead to damage that vehicle warranties won't cover. Worse, deliberately thwarting or inadvertently compromising these automated systems can lead to decreased or altered functionality. Thus, consumers are awakening to the importance of buying ADAS-friendly products from knowledgeable suppliers and/or engaging trusted shops to install them.

DISCOVERING OPPORTUNITY

Against that backdrop, ADAS offers a real opportunity for industry businesses able to grasp how these systems can work in tandem with aftermarket parts and accessories--and that's where the SEMA Garage Detroit's research comes in. Built with specialized facilities and staffed with experienced personnel, the garage is making groundbreaking progress in understanding the interplay between ADAS and aftermarket modifications, starting with the '22 Chevrolet Silverado. The goal is to share SEMA's ongoing findings with the aftermarket community so that businesses can continue to produce compliant product and modify with confidence.

"ADAS has been around for about 15 years, but it started in luxury vehicles and didn't so much affect our SEMA membership," observed Muller. "So we've known the spread of this technology has been coming. Now it's ubiquitous and, fortunately, we're already doing something about it."

To help guide its research, SEMA set up an advisory panel of member manufacturers, modifiers and installers to recommend vehicles for study. But with so many vehicles out there, where was the best place to begin?

Reasoning that suspension components, wheels and larger tires for pickups and SUVs are perennially among the most popular parts in the specialty-equipment aftermarket, trucks seemed a natural choice.

Moreover, vehicles equipped with those aftermarket products are among the most likely to need recalibrating of OE ADAS sensors. Any change in tire diameter, rake angle or vehicle ride height could affect sensor readings and necessitate reworking of an ADAS system.

The advisory panel zeroed in on the stock, baseline Silverado 1500 LTZ due to its popularity. This particular Chevy's sensor suite included a forward-facing camera behind the front windshield, rear corner radars mounted behind the rear bumper, and ultrasonic sensors mounted in the front and rear bumper.

The panel recommended three common scenarios for evaluation. The first involved installation of a 2-in. leveling kit and 33-in. tires; the second, a 3.5-in. lift kit on 33s; and the third, a 6-in. lift kit on 35s. The truck was tested after each modification, then recalibrated according to OEM procedures, and 15 test runs were completed for each individual scenario. The systems tested included the vehicle's lane-departure warning (LDW), lane-keep support (LKS), crash-imminent braking (CIB, aka AEB), traffic-jam assist (TJA), blindspot detection (BSD) and rear cross-traffic alert (CTA) functions.

THE TESTING

Devising a definitive testing process for any suite of ADAS systems is daunting. Because of the many variations of OEM systems mentioned previously, testing conducted on one particular vehicle may not apply to another. And then there is the issue of what criteria should be applied to evaluate success or failure. Due to the lack of a current Federal Motor Vehicle Safety Standard (FMVSS) for any ADAS function, compliance is a moving target.

However, NHTSA has conducted a series of its own confirmation tests and performance evaluations (see nhtsa.gov/equipment/driver-assistance-technologies), so these provided the framework for SEMA's evaluations of the Silverado. They were as follows:

• Lane Departure Warning (LDW): Testing of both left and right lane departure per NHTSA Lane Departure Warning System Confirmation Test, February 2013.

• Lane Keep Support (LKS): NHTSA Lane Departure Warning System Confirmation Test, February 2013.

• Crash-Imminent Breaking (CIB): NHTSA Crash-Imminent Brake System Performance Evaluation for the New Car Assessment Program, October 2015.

• Traffic-Jam Assist (TJA): NHTSA Blind-Spot Detection System Confirmation Test (Working Draft), May 2020.

• Rear Cross-Traffic Alert (RCTA): Custom test procedure, based on concepts from similar global tests.

SEMA's dynamic tests took place at the leading research and testing facility, and were done in several, incremental rounds for each of the modification scenarios.

Rake angles were also diligently evaluated for their influence on the truck's ADAS operations. The test results indicated that forward-facing camera functionality (LDW, LKS, CIB, TJA and AEB) as more impacted by the vehicle modifications compared to rear radar functions (BSD, RCTA). The latter showed very little difference in the test results for the particular Silverado and option package used in the study.

After each modification, the vehicle's ADAS features were recalibrated.

Overall, the testing generated extensive data sets, which are still being evaluated. Still, the preliminary findings suggest some interesting, positive trends and patterns. The study is expected to ultimately give the industry's installers, manufacturers and customizers assurance that with re-calibration,they can continue their work in ways that won't compromise safety systems.

"The bottom line is the modifications tested on the Silverado, along with the accompanying ADAS recalibrated systems, met the overall NHTSA NCAP evaluation criteria, comparable to the OEM stock configuration on the '22 Chevy Silverado LTZ," Muller says.

But again, he emphasizes, "These results are for this one particular vehicle; they should not be viewed as reflective of how any other vehicle might perform, comply or fail. Every vehicle, even within the same model year might be different due to their different equipment features. It's important not to construe this data to apply across the board to other vehicles or modifications."

But after all, this is the entire point of SEMA's commitment to continued research in this area. "What we're doing will hopefully benefit numerous industry stakeholders, including automotive glass companies, collision repairers and insurance companies, specialty-equipment parts manufacturers, modifiers and installers, and the growing number of ADAS calibration businesses and equipment suppliers," said Muller. "At the bare minimum, the current testing supports a best practice for installers and repairers that recalibrates each ADAS system according to OEM service procedures."

NEXT STEPS

So what's next for the SEMA Garage Detroit ADAS Research Center? "Our research and an increased understanding of how aftermarket parts will exist with ADAS has just begun," answers Muller. "We're now moving on to the Ford F-150, and we expect to also study the Dodge Ram and Toyota Tacoma. For now, we'll skip the Toyota Tundra because it's going to be redesigned. But we will be working on the Nissan Frontier. So basically we're starting with GM, Ford, Dodge, Toyota and Nissan, which are among the most modified vehicles in North America."

"ADAS builds on itself," Muller added, so the landscape faces constant change. "For example, we're now to the point where a camera is doing automatic emergency braking at 25-40 mph within the current guidelines from NHTSA. But we also know that the future guidelines will be for higher speeds and even pedestrian automatic emergency braking (PAEB). Here again, this is a great example of the progression of technology."

Another thing to keep in mind is the limitation of ADAS. Even as the aftermarket grows in its know-how to modify newer vehicles, specialty businesses will have to assist with consumer education.

"ADAS is a still a driver-assistance technology, with an emphasis on 'assistance,'" Muller underscores. "It's not intended as an autonomous vehicle technology."

Still, Muller and the SEMA Garage team remain enthusiastic about the challenges ahead. "I'm excited by new technologies, ADAS is just the next progression of automotive tech. "Ultimately, I like helping people, and the SEMA Garage ADAS Technology Center is a great way for us to combine automotive technology with helping others succeed."

VISIT SEMA GARAGE AT THE 2023 SEMA SHOW

The SEMA Garage, located in Diamond Bar, California, and Detroit, Michigan, provides SEMA member product developers with access to the latest technology tools and services alongside a team of engineers to help product developers bring their innovations to market. Attendees of the 2023 SEMA Show can learn more about SEMA Garage and its services and programs--including ADAS, product development, emissions compliance and testing, electric vehicles (EVs), alternative fuels and powertrains, shop and training facilities, OEM CAD data and 3D scanning, and more--at Booth #36007 in the South Upper Hall, October 31-November 3 in Las Vegas.

Editor’s Note: SEMA News Managing Editor Douglas McColloch and former SEMA

News Vice President and Editorial Director John Stewart contributed to this report.