PRESENTED BY MOTHERS POLISH

Andy Leach of CAL Automotive Creations Takes Top Honors for 2023

By Douglas McColloch

Photography by Jason Lubken

Custom car builders hailing from all parts of North America entered SEMA’s Battle of the Builders

Presented by Mothers Polish competition at the 2023 SEMA Show as seasoned competitors jostled with first-time entrants looking to establish themselves. As was the case in 2022, the event featured judging in four distinct vehicle classes: Hot Rod/Hot Rod Truck; Four-Wheel Drive/Off-Road; Sport Compact/Import Performance/Luxury and Exotic; and Young Guns (age 29 and younger).

For 2023, roughly 180 BOTB entries made the trip to Las Vegas for the SEMA Show, where their numbers were subsequently whittled down by a panel of industry experts to a Top 12, three in each category. At that point, the 12 finalists took turns judging each other’s work to determine the winner of each category as well as the overall champion.

For 2023, the class champions were Andy Leach (Hot Rod/Hot Rod Truck), Jared Hancock (Four-Wheel Drive/Off-Road), Jordan Henke (Sport Compact/Import Performance/Luxury and Exotic), and Charles Spencer (Young Guns). When the votes were all tabulated, Andy Leach took top overall honors and best overall build for his stunning ’60 Buick Invicta Custom “X60.”

The four class champions of this year’s competition were highlighted along with other featured builders in a TV special, “SEMA: Battle of the Builders,” which aired on A+E Networks’ FYI and History’s Drive block last month. Check your local

listings for repeat broadcasts.

For this issue, we’re taking a closer look at the winning vehicle, the Nebraska shop where it was built, and the work that went into making it. We spent some time with Andy Leach of CAL Automotive Creations to discuss the evolution of a show-winning build, and the business of building in general.

HOW IT STARTED

“Growing up, I was always into art.” Leach admits, and his passion for art shows in his award-

winning builds. An Omaha native, Leach acquired his first car, a ’37 Ford, at age 14, and it marked the beginning of a lifelong passion. “That was definitely the fork in the road where the love of art transitioned into a love for cars,” he says.

A student at Concordia University in Seward, Nebraska, he enrolled in design classes that supplemented his mechanical skills, and he graduated in 2000 with a degree in commercial art. “I think my professors got mad at me because all the graphic design stuff that I did was based around CAL Automotive. They probably thought I was crazy.

“I always knew that I wanted to build cars. That was my thing from day one.”

After a six-year stint at Troy Trepanier’s Illinois custom car shop, Leach began a collaboration with homebuilder and hot-rod enthusiast Ron Cizek in 2008, helping to build Cizek’s ’40 Ford roadster in a rented shop space near Omaha. “At first, it was just rust repair and stuff like that,” Leach says, “but pretty quickly, Ron saw that I wanted to do more than rust repair and that hot rods were my passion.”

With support from Cizek, Leach launched his own business, CAL Automotive Creations in Bennington, near Omaha. (The acronym “CAL” denotes the initials of Leach’s name; his first name is Christopher.) “Ron showed me the ropes of the business, and I appreciate everything he has done for me,” he says. “I owe a lot of credit to him because I wouldn’t be where I am without him. He was almost like a father figure to me.” Given carte blanche by Cizek to build the Ford any way he wanted, he began the process of “cutting away every square inch of metal from the car and hand-making everything.”

Work on the Ford didn’t stop until 2013, when Leach trailered the completed car to Michigan to display at Detroit Autorama, home of the prestigious Ridler Award. The build had drained him of much of his energy and finances—”I had maybe $10 to my name,” he admits—and he was “scared of what was going to happen” when the Ridler judging took place. To his astonishment, his Ford, “Checkered Past,” was named the 50th Anniversary Ridler winner. “I don’t remember much after that,” he says—at least until he returned to his shop, where his phone was ringing nonstop for days on end. “We’ve been on a dead sprint since then,” he says.

HOW IT’S EVOLVED

Since then, CAL Automotive Creations has grown into a thriving customization business with multiple awards to its credit, 12 full-time employees and an equally full workload: “We typically have a dozen builds going on at any given time,” he says.

That isn’t to say there haven’t been some bumps in the road along the way. “It’s been a learning experience,” Leach says, admitting that “When I started this, I didn’t know anything about business.” Since then, he has learned to wear two hats—one as shop manager and the other as business manager. “I’m a guy that likes to be in the shop, not a guy that likes to sit behind a desk and do the business stuff. It’s still a tough balance because I prefer to be in the in the shop, and I am in the shop 90% of the time.”

With so many builds going on at once, it’s essential to develop a system to keep the workflow smooth and organized. “We take them in the order they arrive at the shop,“ Leach explains. “First, the cars fall into the fab side, where all the fab work gets done. Then we typically take them over to the assembly side, where we wire and plumb them and get them to a drivable running state. Then we take them out and put at least 500 mi. on them to work all the bugs out of them.

“Once we feel that the car is pretty much solid mechanically, that’s when we blow it apart,” he continues. “The car goes to body and paint, and then to final assembly after that. It’s kind of an assembly line process.” Leach credits his employees, “a great group of guys who are very passionate about what they do,” for making the shop run efficiently.

Still, there are builds and then there are builds. “Not everything we build is built like the Buick,” Leach admits. “Some of them are simpler, where the car gets a new chassis and crate motor and other things that aren’t so time-consuming.”

A WINNING BUILD

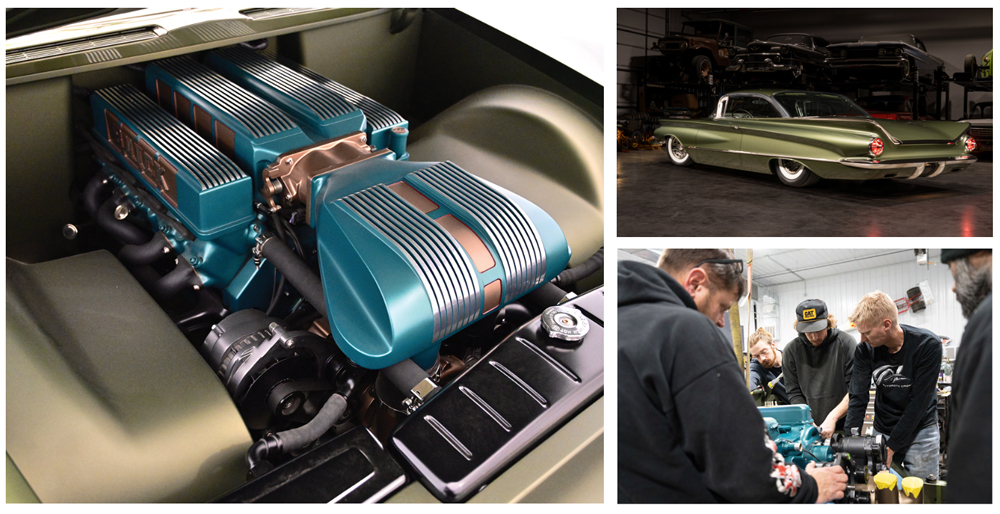

Every client is different in his own way, Leach explains, but when ’60 Invicta owner George Eliacostas turned up at Leach’s shop in 2014, his proposal was simple and direct: “‘Here’s the Buick,’ he said. ‘What do you want to do with it?’ I said, that’s such a cool car. We’ve got to keep the ’60 Buick look and feel and just refine what’s already there. Eventually we came up with the idea of a ’59 GM Motorama-type vibe, a concept car.” Thus began a nine-year project involving a dozen skilled technicians and “more man-hours that I want to think about.”

When asked to choose the most technically demanding element of the build, Leach replies. “The whole car. We pushed every aspect of this car as hard as we could,” As an example, he points to the Buick’s Nailhead V8 engine, which was retained “to preserve the Buick aspect” and which was fitted with a crank-mounted Procharger and a custom front accessory drive that by itself took “a year’s worth of modeling to execute. There are more than 300 machined pieces just in that front drive area.”

The Buick’s nine-piece interlocking wheels, with integrated faux white sidewalls, were a novel feature that involved some lengthy experimentation. Leach credits designer Eric Black for much of the inspiration. “We took a couple of different approaches to it, and we finally agreed to keep the ‘hubcap look’ that a lot of guys are doing right now with their wheel designs, but one that had depth and dimension to it. So Eric did a drawing of a kind of hubcap-looking wheel with a fake whitewall, which led to the idea of creating a wheel in layers, with different finishes on each layer. We started with two or three layers, and it just kept evolving and evolving, and that’s how we ended up with a nine-piece layered wheel.

“George kept letting us go,” Leach says of the Buick’s owner. “He just said, keep going to create the best thing we could possibly create. And that’s what I feel we did.

“We engineered every piece on that car other than the four tires and the cast engine block and heads,” Leach says. “Everything else on the car was custom-built.”

While CAL Automotive Creations has numerous awards to its credit, including the Al Slonaker Memorial Award at the 2023 Grand National Roadster Show (which was won by the Buick), Leach points to winning Battle of the Builders as a signature achievement. “Battle of the Builders is the one,” he stresses. “You know, a lot of these awards are about the cars, but here you finally get one that recognizes the builder and the build team, so it’s very rewarding. It’s kind of a dream come true.”

At Battle of the Builders, the finalists judge each other’s work, which Leach finds especially gratifying. “There are shows where you have judges who don’t build the cars and who don’t fully understand everything that goes into them—particularly all the modern technologies” that today’s builders need to master to stay on top of their game.

“Ten, 15 years ago, we were barely machining parts. Now, suddenly, everything’s machined. Now, everything’s 3D-printed. It’s crazy how quickly this thing is evolving, and it has really raised the bar for all of us to keep putting fresh stuff out there.”

When Leach judges another builder’s work, he adheres to a simple principle. “The very first thing I ask is, is it a pretty car? Does the thing visually work when you step back? It’s great to make a lot of modifications, but doing modifications just for the sake of doing modifications doesn’t

impress me. So first thing, is it a pretty car? How’s the stance, the tire size and the attitude of the car? That’s the first thing that grabs me. And then as I approach the car, ’ll dig into the details.”

Leach also manages to find the time to build cars for himself, including a ’61 Mercury unibody pickup-in-progress that he plans to use as his “shop beater” this coming spring. A self-professed “‘62 bubble-top nut,” he’s the owner of a couple of ’58–’62 Chevys, a low-mileage ’59 Pontiac wagon, and a ’59 Oldsmobile two-door hardtop, to name a few.

“I have too many cars,” he smiles. “It’s a disease.”

To aspiring builders who are thinking of starting a similar business, Leach’s advice is straightforward: “Just build the best car you can possibly build and get it out there. People will find you the same way they found me.”

THE CAL AUTOMOTIVE BUILD TEAM

Andy Leach: Owner

Grant Currington: Fabrication and Assembly

Earl Boldra: Machining

Erik Hanson: Design & Fabrication

Ethan Jansen: Bodywork

Rick Ulfers: Assembly

Matt Summers: Paint & Mechanical

Paul Caruana: Lead Fabricator

Sam Gengenbach: Assembly & Fabrication

Scott Schneckloth: Bodywork

Steve Socha: Fabrication

SPECIFICATIONS

Owner: George Eliacostas, Chicago, IL

Builder: Andy Leach, CAL Automotive Creations, Bennington, NE

Vehicle: ’60 Buick Invicta Custom “X60”

Engine: 401ci Buick Nailhead V8; smoothed and polished block and heads; one-off billet main caps and crankshaft

Aspiration: Sequential EFI with single throttle body; crank-driven Procharger supercharger

Transmission: GM 4L80E automatic with billet pan

Suspension: Four-link independent; custom-machined upper, lower control arms, trailing arms; Penske coilovers

Steering/brakes: Custom power steering with modified ‘64 GM column/Baer discs with six-piston (f), four-piston (r) calipers

Wheels: 19x8 (f) and 19x9 (r) custom nine-piece interlocking with faux machined white sidewalls

Tires: 255/40R19 (f), 265/50R19 (r) Pirellis

Interior: Relicate “Cordaveen” Green leather, Che-Se Diamond cloth by Starline Hot Rod Interiors

Exterior: Custom Inverde Green by Painthouse

Special features: Basically everything, but we’ll mention the bodywork wedge-sectioned 2 in. in front; one-piece rear bumper; one-off taillight bezels; Invicta Custom hardback bucket seats; machined seat trim with Invicta logos and courtesy lights; custom-machined center console with hidden cupholders and charge port; suspension links pocketed between

framerails; Wonderbar radio with Bluetooth capability; Dakota Digital gauges; Vintage Air A/C; custom woven aircraft carpet.

BOTB 2023: THE OTHER CLASS CHAMPIONS

To make the final four at Battle of the Builders, customizers need to display unparalleled artistry and superior mechanical skills, and their vehicles must evidence meticulous assembly and

flawless execution. The following pages feature a look at the three other deserving class

champions at BOTB 2023.

FIRST TIME’S A CHARM

Builder: Jared Hancock, J-Rod and Custom, Black Diamond, WA

Vehicle: ’78 Jeep Cherokee Chief

Category: 4-Wheel Drive/Off-Road

While Jared Hancock’s hot-rod shop, J-Rod and Custom, has been in business for some 20 years, he admits that this ’78 Cherokee Chief, a four-year project, represents his shop’s first-ever Jeep build. It’s also the first Jeep to ever finish in the Top 4 at Battle of the Builders, and it wasn’t any easy project to take on.

One major challenge facing Hancock’s team going in was the fact that Jeep build tolerances of the ’70s left much to be desired, and many months of bodywork were required to get all the panels properly fitted and aligned. All body lines were painstakingly sharpened and straightened via months of arduous taping and sanding, and new door skins were fabricated to maintain a smooth exterior flow. The bumpers were narrowed and tucked, and the stock grille was refinished by Ogden Chrome and fitted with custom aluminum trim.

Once the sheetmetal was ready for the spray booth, custom-blended gold paint with black-diamond accents (called “Griot’s Gold,” in honor of the vehicle’s owner, Richard Griot of Griot’s Garage) was applied by Randy Borcherding at Painthouse, and atop the bodywork, a flush-fit panoramic glass roof is outfitted with a one-off rack with matching diamond accents.

Under the hood, residing between the rails of an Art Morrison chassis, is a “connect and cruise” GM drivetrain that’s powered by an L96 6.0L crate motor (with diamond-

accented valve covers) that’s paired to a 6L80E automatic transmission. Power is transferred to a set of custom-painted 17x8.5-in. Fifteen52 rims sporting 3D-printed center caps and wrapped with 285/70R17 BFGoodrich KO2 tires. Suspension duties, front and rear, are handled by links and coil springs, and 14-in. Baer discs equipped with six-piston custom-painted calipers bring the ride to a halt.

The Jeep’s interior continues the gold-and-black color scheme in a subdued and subtle fashion. Stitchery was handled by McFarland Upholstery, with two-tone leather applied to the stock seats and door panels. The instrument panel features brushed and sandblasted stainless that was etched with a matching diamond pattern.

BACK TO THE FUTURE

Builder: Jordan Henke, JH Restorations, Windsor, ON, Canada

Vehicle: ’87 Merkur XR4Ti

Category: Sport Compact/Import Performance/Luxury and Exotic

Nicknamed “RS4Ti,” Jordan Henke’s rolling tribute to the ’80s was inspired by the iconic Euro-spec Ford Sierra RS500, and was built, in Henke’s words, to be a “Cosworth clone.” The car had been largely stripped for parts when Henke took possession of it, and he first turned his attention to the engine bay, where a turbocharged Pinto 2.0L normally would have resided. Now, a 2.3L Mustang EcoBeast short-block sourced from Ford Performance provides motive power, and its relatively tall height required the carbon-fiber hood to be raised in the center. The engine bay has been shaved, and the relocated battery sports Nintendo game stickers to accentuate the ’80s theme.

The newly swapped engine necessitated some front suspension adjustments, which gave Henke the opportunity to increase the track width of the car—and with it, the impetus for a custom widebody kit. The new 4-in.-wider body extends from bumper to bumper. In all, every panel was modified save the doors and the roof skin. The body kit also gives the RS a lowered appearance with the addition of side skirts, a front splitter and a rear diffuser. The body is coated in Ford Area51 blue paint with orange accenting.

Beneath the widebody, a Tremec TKX five-speed transmission transfers power to a Ford

8.8-in. rear axle, which in turn spins a set of American Racing VP529 wheels equipped with Toyo Proxes tires and 14-in. Wilwood discs. The re-engineered suspension utilizes Corvette hubs and QA1 coilovers.

Inside, the interior was kept mostly stock, though leather now wraps the seats and dash and the carpet has been upgraded to Daytona Weave Blue. The modern-day Ford Focus RS front buckets feature classic Recaro fabric inserts with a color scheme that carries through to the door panels. Headrests were sourced from a Fox-body Mustang, and the color-matched “Fun Haver” steering wheel pays tribute to Vaughn Gittins’ Ford RTR race team. Dakota Digital-rebuilt gauges rest inside the instrument panel, and the Blaupunkt stereo is Bluetooth-enabled.

ALL IN THE FAMILY

Builder: Charles Spencer, Charly’s Garage, Mesa, AZ

Vehicle: ’69 Chevrolet C10

Category: Young Guns

An after-school project, Charles Spencer’s ’69 C10 was a four-year build that he began at the age of 14. With the aid of “my dad, grandpa, and brothers,” he completed the truck in time for the 2023 SEMA Show—and at age 19, he’s the youngest-ever Battle of the Builders Young Guns champion.

Admitting the truck was “in pretty good shape” when he acquired it, Spencer nonetheless tore down the truck to the frame to remove some rust spots from the bodywork. The frame was sent out for powdercoating, then outfitted with a Ridetech suspension before the cab was lowered onto the frame. Body panels were gapped and straightened, and then finished in lustrous Axalta Indigo Blue paint applied by Spencer himself. Up front, the bumper was smoothed and tucked, and the chrome grille was masked off and the recesses painted to match the body. In the rear, a custom-smoothed tailgate features a recessed latch, one-off hinges and a Rhino-Lined bed finished in matte blue to contrast with the gloss paint. All headlights, taillights, turn-signal and marker lights are LED units. The gas tank was relocated rearward, with a custom filler now accessed via the truck’s bed.

Under the hood, a 350 Chevy V8 donated from Charles’s grandfather’s Ford roadster is fortified with Comp Cams internals. FAST fuel injection provides aspiration, a custom Flowmaster 50-series exhaust expels spent gases, a Ron Davis radiator enables cooling, and a Billet Specialties serpentine system ensures all ancillaries are functioning. The engine bay is finished in matte blue with a smoothed firewall, and a one-off hood latch makes engine access easier. Power flows to a set of 20-in. U.S. Mag wheels spinning Nitto NT555 ultra high-performance tires; four-piston caliper Wilwood brakes provide stoppage.

Inside the matte-blue cab, a set of TMI bucket seats are finished in medium satin

slate upholstery to complement the exterior color scheme. The stock instrument panel hosts Dakota Digital gauges, and a Pioneer stereo system has been installed. Vintage Air keeps the cab cool on hot days, and an ididit steering column is finished in matching

matte blue.