By Gordon Paden

For as long as the National Hot Rod Association (NHRA) has been scorching quarter-mile strips across America, the heart of drag racing has been thumping to a familiar beat: old-school Detroit iron. From the early days of NHRA, it has been dominated by the tried-and-true heroes of the 1960s and ’70s… Carbureted Small and Big Block GM engines, and their Mopar and Ford counterparts. These engines, born in the golden era of American muscle, have been the backbone of the sport, built tough, modified hard and loved by generations. But hold on to your HANS device folks, because there’s a new trend popping up in the pits, and it’s all about modern muscle. That’s right: we’re talking EFI, coil-on-plug ignition, computer-tuned powerplants where the crew spends more time looking at the laptop, than reading spark plugs and changing jets!

Over the past few seasons, a quiet movement has been slowly making its way into the national and regional events. Nowadays when you walk the pits, you can spot a few competitive contenders packing the modern Gen III Hemis, LS/LT-based monsters and Ford’s latest Coyote platforms. These aren’t just considered street class and outlaw no prep engines anymore, they’re laying down consistent ETs good enough for NHRA’s tight competition and they are turning heads while doing it.

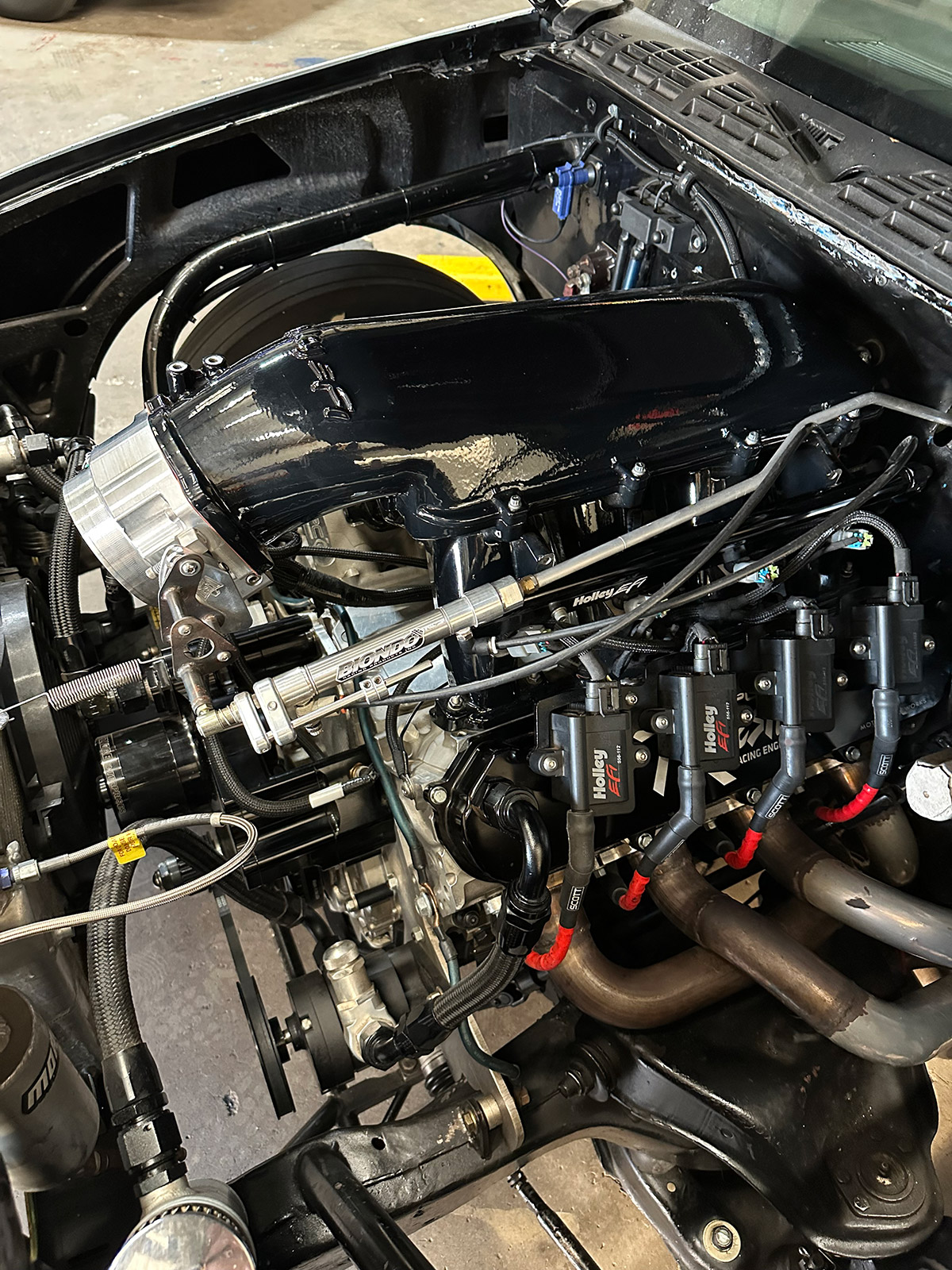

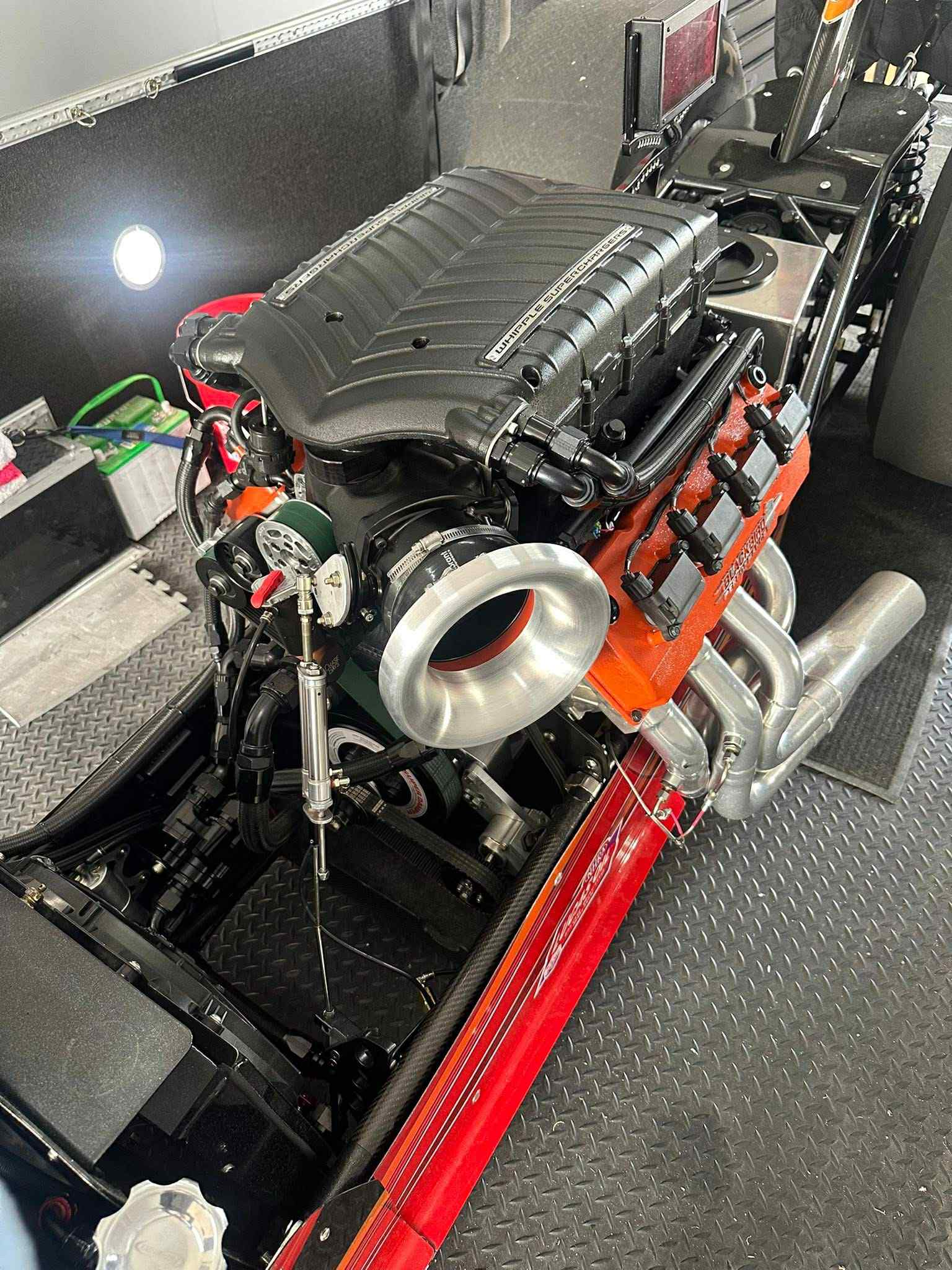

One of these racers is SDPC Raceshop driver Bailey Estes-Alonzo who took home the final win light in the Super Street 10.90 Class at the second race of the NHRA Division 5 Season opener in her S10. Nestled between the frame rails of her truck sits an SDPC Raceshop Gen V LT, with 412 cubic inches and 14.5:1 compression ratio. Combine that with the consistency of Holley EFI port fuel injection, and coil-on-plug, this combo handles the 10.90 class with ease. Another recent standout is Kevin Burnett’s rail car. Kevin decided to forgo the classic recipe in his rail car, instead of installing a carbureted big block, he opted to swap in the Blackbird Performance Whipple supercharged “Race Spec 1,650HP” Hemi engine. Sporting a modern port EFI system with coil on plug, it was able to lay down a 6.457 @ 212.63 MPH at the Rocky Mountain Top Dragster event! It may lack the nostalgia of a locked-out timing Big Block Chevy rumbling the ground as it idles by, but at 1,600 horsepower and mid 6s in the ¼ mile at over 200 mph, it’s got performance you can’t ignore.

For decades, the formula was simple: grab a big block, slap on some big valve heads, a big cam, big carb, and go racing. The parts were plentiful, the knowledge was deep, and the results are consistent. As these engine blocks continue to age and donor motors become harder to find, the cost of building traditional platforms is steadily increasing. At the same time, many manufacturers are phasing out, and/or discontinuing the essential supporting parts, making it even more difficult to keep these aging engines alive. Meanwhile, modern engines are just lining shelves at salvage yards across the country, and they come with factory-installed roller cams, efficient combustion chambers, and heads with stock airflow figures the seasoned guys only dreamed about. Add in aftermarket support that’s exploded in the past couple of decades, and it’s easy to see why some forward-thinking racers are making the jump.

Now let’s be clear, this is far from the funeral for the traditional V8s. There’s still something visceral about the sound of a 15:1 Compression 582 Cubic inch big-block screaming at 8,000+ rpm on a full pass. And in all the NHRA classes, you’ll still find fields filled almost entirely with vintage big blocks, carburetors and distributor setups that haven’t changed since Reagan was in office. But in the open classes, and especially among the newer generation of racers that are embracing the newer technologies, modern engine architecture is starting to gain attention.

In conclusion, both Drag racing and the NHRA were born from innovation. From the 1930’s hot rodders bolting random parts onto whatever car frame they had and racing across the dry lake beds in California, which transitioned to today’s racers who embrace EFI, CAN-bus data logging, and modular engine tech. These modern engine racers aren’t abandoning that tradition; they’re redefining it. Whether it’s an all-aluminum naturally aspirated Gen V LT1 making 900 hp, or a stock-bottom-end 10 speed Coyote with a 150-shot surprising everyone on Test and Tune night, one thing’s for sure: the future is showing up to the lanes, and it isn’t going anywhere, it’s just getting started. Next time you're in the pits and hear the high-pitched whine of a fuel pump drowning out the sound of the engine rumbling the pavement, and a tuner hammering away at the keyboard inside, don’t roll your eyes. Lean in, watch, and try and learn something. That sound you’re hearing? It’s the sound of progress, and it’s coming for the win light.